Manual drilling tapping compound machine

Equipment description and pictures

1.The manual working machine consists of a base, a column, a lifting table, a middle trailer, a working table and a spindle unit

PLC Control Program Control, man-machine interface friendly dialogue, intuitive programming easy to operate, ordinary people can quickly learn

2.Sliding sleeve type double spindle manual feed unit, Korean imported pneumatic transmission worktable. The table adopts pneumatic device and hydraulic buffer positioning, moving, positioning accuracy is high. Eliminates the old-fashioned equipment easy to appear the screw thread does not malfunction

3.Worktable after high-frequency processing, wear-resistant, high-temperature, equipped with Lubrication System

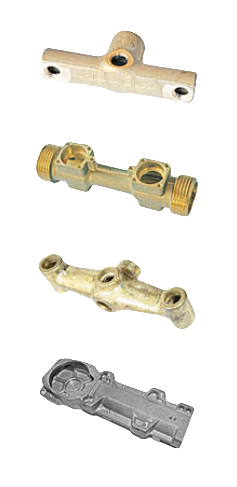

4.Applied to valves, plumbing sanitary ware, door control hardware, fire hydrants, auto parts and other processing, easy to operate, beautiful appearance, cost-effective.

Automatic Equipment description and photos

Technical Parameter

| Parameter name | Unit | Model | ||

| ZS4132×2 | ZS4132×2A | ZS4132×2B | ||

| Diameter of spindle sleeve | MM | 86 | ||

| Number of cutting spindles | / | 2 | ||

| Transmission Mode | / | Single Motor Synchronous Belt Drive | Single Motor Gear Drive | FIRST-STAGE BELT DRIVE |

| Maximum dilling diameter | MM | 32 | ||

| Maximum tapping dimeter | MM | 32 | ||

| Spindle taper | # | NT30 | ||

| Spindle pitch | MM | 150 | ||

| Distance between spindle end face and worktable surface | MM | 260-580 | ||

| Dimension of Work Table | MM | 600*230 | ||

| Table Travel(X) | MM | 160 | ||

| Middle Tow travel(Y) | MM | 120 | ||

| Spindle travel (drilling / tapping) | MM | 110/110 | ||

| Manual / Automatic Tapping | / | Manual Operation | ||

| Drilling spindle speed | Rpm | 1420/990/619 | 874/1382 | |

| Tapping spindle speed | Rpm | 580/410/257 | 575/908 | |

| Type of drilling motor | / | 3KW/4P3KW/4P | ||

| Type of tapping motor | / | |||

| Total Power | kw | 3 | 6 | |

| Dimensions (length * Width * Height) | Mm | 1200*680*1600 | ||

| Machine Weight | kw | 700 | 750 | |

Display of processed products